How did the semiconductor crisis get so bad? What is the strategy that the Indian government is deploying to become an abortionist in this situation?

The semiconductor crisis is one of the most critical economic threats looming over the world economy for one year. This crisis has been so bad that apple lost 6 billion in revenue, Maruti had to cut down 60 of their production, Mahindra had to cut down 20 of its production and the auto industry itself has already lost 100 billion dollars in revenue due to chip shortages. India is one of the largest and fastest-growing electronic markets in the world our economy is again vulnerable to a massive threat due to this crisis.

Starting from the basic’s semiconductor chip is the brain of any electronic device and they are responsible to conduct every small action in our electronic devices and cars. For example, your mixer controls the speed of the motor, in a car, there are hundreds of semiconductors that handle everything starting from your keyless entry to automatic dose and even the functioning of your engine. Today in this digital world that we live in, semiconductors are the most important components that keep the world functioning starting from mobile phones to the biggest servers in the world. They are as important if not more important than the internet itself.

Why is there a sudden shortage of semiconductors? What is its impact on different industries?

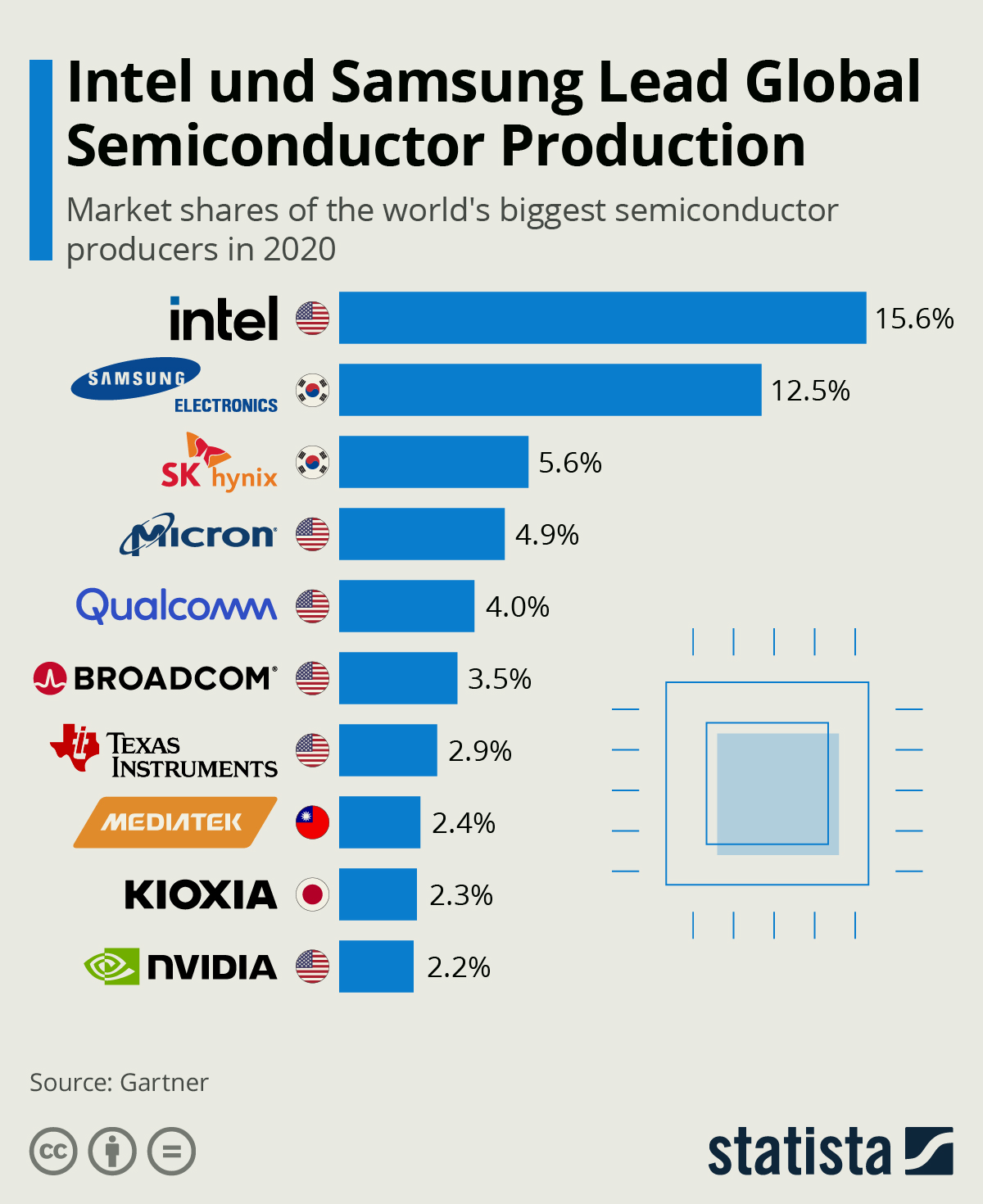

The first reason for this shortage is that the industry had already been growing rapidly that it was already at the brink of shortage. According to the semiconductor industry, today more than 100 billion integrated circuits are in use every single day all across the world which is equal to the number of stars in our corner of the milky way galaxy. This market is so huge that even with giant players like Intel, Micron, Nvidia, AMD, and QUALCOMM there still isn’t enough supply to cater to the skyrocketing demand. Therefore, when the pandemic hit on one side while the demand for electronic gadgets skyrocketed due to work from home on the other side due to the temporary shutdown of factories and shipping services the demand went way beyond the supply capacities. This shortage is so difficult to recover because manufacturing a microchip typically takes more than three months and involves giant factories, dust-free rooms, multi-million-dollar machines, molten tin, and lasers. Since the manufacturing cannot be increased on such short notice, the wait times for chips are increasing at an alarming rate, going from 11.8 weeks in September 2019 to 21 weeks in august 2021. Meanwhile, according to statistics, the chip industry that was already worth 440 billion in 2020 is estimated to grow to 550 billion in 2021 and will touch 600 billion dollars by early 2022 and this drastic difference in supply and demand is the reason why companies from all across the world from different sectors have started facing production issues.

The four major industries that face heat are the Auto industry, LED lighting industry, Consumer electronics industry, and the appliance industry. In the Auto industry, Ford and General Motors of the US have been drastically affected in India. We saw in just the second quarter of 2022 Maruti could not produce an estimated 1.16 lakh vehicles due to the semiconductor shortage. This is the reason why Maruti’s output was nearly down by 60 in September to just before the festive season in India. In consumer electronics, HP raised the price of its printers by 20% on an average in a single year. Sony said that it will not produce adequate supplies of its PlayStation 5 console until 2022. Similarly, a large number of companies have been deeply affected by the semiconductor shortage of the world. This is when many countries including India realize that it is super important to be a part of the semiconductor ecosystem and it is high time that we decrease our dependence on other countries merely by being the customers of semiconductors.

What is the position of India in the semiconductor market? What is the government doing to de-risk this situation?

Despite having intel micron and Samsung housing their R&D centers in India, we have nothing significant in chip manufacturing. If you look at India’s semiconductor trade situation while we exported 425 million dollars worth of semiconductors in 2020, we imported 10.59 billion dollars’ worth of semiconductors and with growing electronics market our semiconductor imports grew by 100% from just 5.2 billion dollars in 2016 to 10.59 billion dollars in 2020. About 40 percent of our imports originate from China and 26 percent come from Hong Kong and we all know how China is notoriously trying to take control of Hong Kong. Therefore, just like solar wafers and ingots, India is again vulnerable to more semiconductor shortages that could cost us billions of dollars.

What is India doing to fix the situation and decrease its dependence on China?

In Quad summit which was a leaders conference held by President Biden on 24th of September 2021 and the agenda was to discuss how to tackle the several economic challenges of respective countries and one of them was the semiconductor shortage of the world. Chip manufacturing is a complex process that requires multiple steps, so if each country sets up 5 divisions for 5 different processes, then it is both costly and time-consuming which is why India, Australia, Japan have decided to collaborate to implement only those processes that are their strengths and pass on the rest to the rest of the countries. For example, the U.S is a global leader in semiconductor design and American companies also dominate in electronic design automation and licensed intellectual property. Japanese companies enjoy a dominant position in semiconductor materials and chemicals that are used for manufacturing chips and Japan is also a market leader in silicon wafers and substrates on which the ICS is been made. Similarly, Australia occupies an important place in the broader electronic supply chain as it has access to critical materials and advanced mining capabilities and the semiconductor design requires a large number of skilled engineers. This is where India comes in the quad summit. Australia, the U.S, Japan, and India have joined hands to build a robust semiconductor supply chain based on their strengths to eliminate their dependence on China Taiwan and Hong Kong. India’s 76 000 crore production lint incentive program comes in wherein the central government of India plans to establish 20 semiconductor units in the country over the next two years. To tackle the semiconductor shortage and de-risk India from China, the government has lined up attractive incentive support for companies engaged in silicon semiconductor fabs, display fabs, compound semiconductors, silicon photonics sensors fabs, semiconductor packaging, and semiconductor design. PLI land, semiconductor grade water power logistics, and research ecosystem will be provided to these companies at subsidized rates to set up two greenfield semiconductor fabs and two display fabs in the country. Apart from this, the Indian Government has designed a linked incentive scheme and the India semiconductor mission. New schemes announced by the government are expected to contribute to the one trillion-dollar digital economy by 2025-26. It has a production target of close to 128 billion dollars over the next 20 years and exports are expected to judge 68.97 billion over the next 20 years. If this happens along with the successful execution of the quad summit agreements, India will go on to become a hub of semiconductors, and more importantly, we will be less dependent on China. This is how India plans to go from being an importer of semiconductors to a major exporter of semiconductors in the global market.

What are the factors that you need to keep an eye on to understand the impact of the semiconductor crisis on the stock market?

The most important part, as investors in the stock market and citizens of India, is if you're keen on investing in specific Indian companies that are now standing up against the Chinese industries. Here are the three important factors that you need to keep an eye on to understand the semiconductor market of India

- Keep a very close eye on the production-linked incentive program of the government and find out which of the public listed companies could become a beneficiary of this incentive scheme and at the same time before this, the government already attempted to rule out attractive subsidies, and yet it failed so do some homework and find out why did it exactly feel?

- India is now partnering with Taiwan which is now sternly opposing the Chinese takeover and India is having this partnership to establish semiconductor units in India. Taiwan is very critical because the Taiwanese contract manufacturers together accounted for more than 60% of the total global foundry revenue last year. It would not be an exaggeration if we say that the world is dangerously dependent on Taiwan for semiconductors.

- Keep an eye on the quad summit fact sheet and how it brings new opportunities to the Indian economy.

If you understand this properly you can then further research and find out which are the public listed companies that will further go on to benefit from these government schemes and hopefully you will go on to find some stock market gems because of this research.

Good information man

ReplyDeleteshare this information for more people to buy the stocks.

Deletevery good, very informative

DeleteBest blog ever very detailed and Informative

ReplyDelete